Hydropower Turbines: Types, Applications, and Global Trade

Author: PPD Team Date: March 9, 2025

At the core of every hydropower plant is the turbine, the mechanical heart of the system. Hydropower works by converting the gravitational potential energy of stored water into kinetic energy as it flows downward. This movement drives a turbine, which in turn powers a generator to produce electricity.

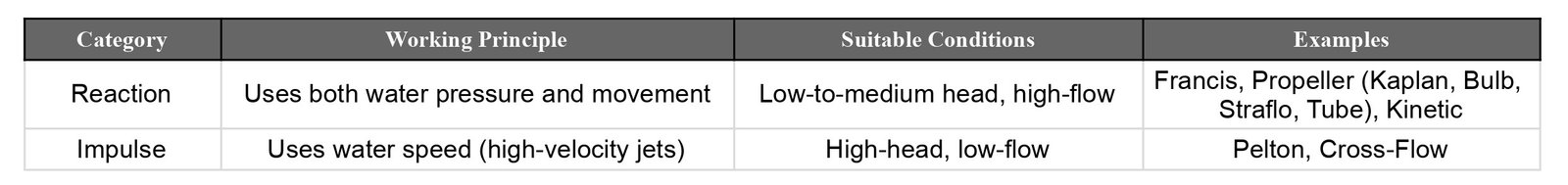

This article explores the different types of turbines used in hydropower plants and how they impact efficiency, cost, and performance. Hydropower turbines fall into two main categories: reaction and impulse. The choice of turbine depends on factors such as the water head (the height of standing water) and flow rate (the volume of water passing through per unit time). Other considerations include installation depth, efficiency, and cost.

Reaction Turbine

Reaction turbines generate energy by exploiting both water’s pressure and movement. Submerged in the water stream, their blades spin as water flows over them, making them ideal for low-to-medium head (height of water drop) and high-flow environments like rivers and large dams.

The most common types of reaction turbines include Propeller (including Kaplan), Francis, and Kinetic turbines.

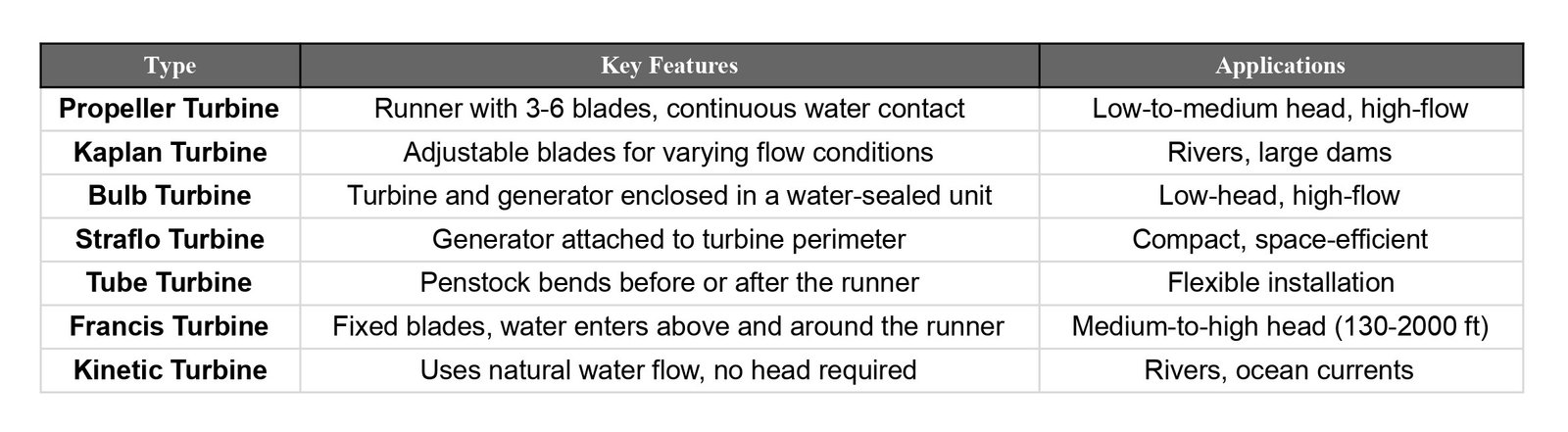

Propeller Turbine

A propeller turbine typically has a runner with three to six blades, with water continuously contacting all the blades. It functions similarly to a ship propeller operating inside a pipe, where the pressure remains constant to prevent imbalance.

The turbine consists of several essential components, including a scroll case, which directs water efficiently, wicket gates, which regulate flow, and a draft tube, which helps recover energy from the exiting water. The versatility of propeller turbines has led to the development of different types, each designed to optimize efficiency in varying conditions:

- Kaplan Turbine: Invented by Viktor Kaplan in 1919, this design features adjustable blades and wicket gates, allowing it to operate effectively across a wide range of water flow conditions.

- Bulb Turbine: Here, the turbine and generator are enclosed in a sealed unit and placed directly in the water stream, reducing infrastructure complexity.

- Straflo Turbine: A unique design where the generator is attached to the perimeter of the turbine, optimizing space and efficiency.

- Tube Turbine: Designed for flexibility, the penstock bends before or after the runner, creating a straight-line connection to the generator.

Francis Turbine

Invented by British-American engineer James Francis in 1849, the Francis turbine was the first modern hydropower turbine. It has a runner with fixed blades, typically nine or more, and water enters just above and around the runner, falling through to spin the blades. Key components include a scroll case, wicket gates, and a draft tube. Francis turbines are widely used for medium- to high-head applications (130 to 2,000 feet) but have also been employed in lower-head conditions. They function efficiently in both horizontal and vertical orientations.

Kinetic Turbine

Also known as free-flow turbines, kinetic turbines generate electricity from the kinetic energy of flowing water rather than the potential energy from head. These systems can operate in rivers, man-made channels, tidal waters, or ocean currents. They do not require water diversion through artificial channels, riverbeds, or pipes, though they can be used in such conduits. Since kinetic systems utilize the natural water flow, they require minimal civil works and can be installed on existing structures such as bridges, tailraces, and channels.

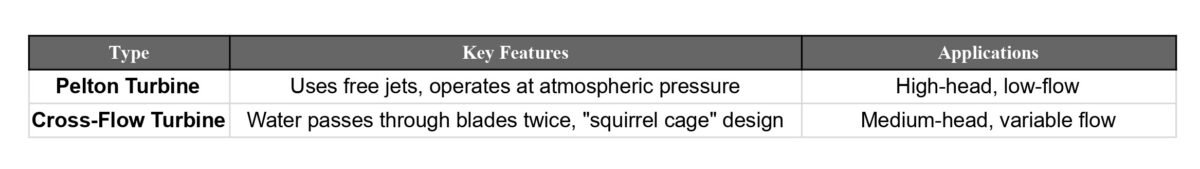

Impulse Turbine

Impulse turbines rely on water’s speed, not pressure. Operating at atmospheric pressure, they use high-velocity jets to strike blades, making them ideal for high-head, low-flow sites like mountain streams. The two main types of impulse turbines are Pelton and cross-flow turbines.

Pelton Turbine

Invented by American inventor Lester Allan Pelton in the 1870s, the Pelton turbine features one or more free jets discharging water into an aerated space, impinging on the buckets of a runner. Pelton turbines are typically used for very high-head, low-flow applications. Since impulse turbines operate at atmospheric pressure, they do not require draft tubes, and the runner must be positioned above the maximum tailwater level to function properly.

Cross-Flow Turbine

The original cross-flow turbine was designed by Austrian engineer Anthony Michell in the early 1900s, later improved by Hungarian engineer Donát Bánki and further refined by German engineer Fritz Ossberger. A cross-flow turbine has a drum-shaped design with an elongated, rectangular-section nozzle directing water against curved vanes on a cylindrical runner. The design resembles a “squirrel cage” blower, allowing water to pass through the blades twice. On the first pass, water moves from the outside to the inside of the blades, and on the second pass, it flows from the inside back out. A guide vane at the entrance directs flow into a specific portion of the runner. The cross-flow turbine was developed to handle larger water flows and lower heads than a Pelton turbine can accommodate.

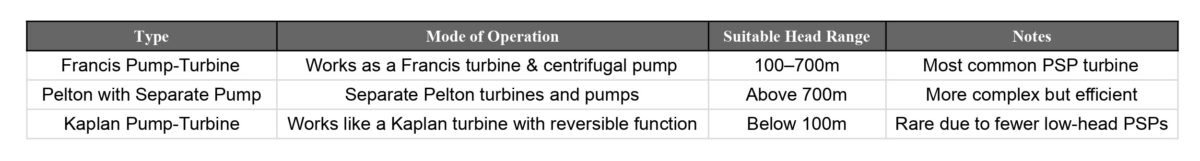

Pumped Storage Plant (PSP) Turbines

While the main categories are reaction and impulse turbines, there are additional specialized and emerging turbine designs used in specific hydropower applications. Here are a few more types:

In Pumped Storage Plants (PSPs), the primary turbines used are reversible pump-turbines that can operate in both generation and pumping modes. The two main types are:

1. Francis Pump-Turbine

- The most commonly used turbine in PSPs.

- Operates as a Francis turbine during power generation and as a centrifugal pump during water storage.

- Suitable for medium to high head applications (typically 100–700 meters).

- Offers high efficiency but requires precise control for switching between modes.

2. Pelton Turbine with Separate Pump

- Used in high-head PSPs (above 700 meters).

- Instead of a reversible turbine, separate Pelton turbines and pumps are used.

- More complex but allows for optimized efficiency in both pumping and generation modes.

3. Kaplan Pump-Turbine (Less Common)

- Used in low-head PSPs (below 100 meters).

- Works similarly to a Kaplan turbine but with reversible functionality.

- Less common due to limited low-head PSP projects.

Most modern PSPs use variable-speed pump-turbines, which offer better efficiency and grid flexibility compared to traditional fixed-speed units.

Global Trade in Hydraulic Turbines

According to the Observatory of Economic Complexity (OEC), in 2023, hydraulic turbines were the 923rd most traded product globally out of 1,217 categories. The top exporters of hydraulic turbines were China ($297 million), Germany ($95.3 million), Italy ($78.4 million), Austria ($74.3 million), and India ($54 million).

The top importers in 2023 were the United States ($67.8 million), Vietnam ($56.8 million), Austria ($41.3 million), Pakistan ($39.7 million), and Tanzania ($38 million).

India’s Hydropower Turbine Industry

In India, the predominant hydro turbines used are Francis, Pelton, and Kaplan types. India’s hydraulic turbine exports were valued at $54 million, accounting for 5.37% of the global market in this category. According to the Central Electricity Authority (CEA), approximately 49.57% of India’s installed hydropower capacity has been sourced from indigenous suppliers, with Bharat Heavy Electricals Limited (BHEL) alone accounting for 42.69% of the total capacity. The remaining 49.93% of the installed capacity has been imported from various countries, including Japan, Canada, the United Kingdom, and France.

Conclusion

According to the International Energy Agency (IEA), hydropower is the largest global renewable energy source, generating nearly as much electricity as all other renewable technologies combined. The ongoing advancements in turbine technology and increasing investments in hydropower infrastructure continue to drive the global adoption of this sustainable energy source.

Featured photograph shows various hydropower turbine designs