Grid Failures: Exposing Gaps in India’s Power Infrastructure

Author: PPD Team Date: June 26, 2025

The Central Electricity Authority (CEA) has released two technical reports on equipment failures in India’s power grid. The first, titled Report of the Standing Committee of Experts on Failure of 220 kV and above Voltage Class Substation Equipment, covers the period from July 2023 to December 2024. The second, Report of the Standing Committee of Experts on Failure of EHV Transmission Line Towers, covers failures between January 2024 and December 2024. Both reports provide insight into the reliability issues affecting transmission infrastructure and highlight areas for improvement.

Transmission tower failures: Key observations

India’s power system relies on high-voltage transmission lines and their support structures—towers—to transport electricity over long distances. Between January and December 2024, 28 incidents involving Extra High Voltage (EHV) transmission tower failures were reported by 12 transmission licensees. These incidents led to the collapse of 68 suspension towers and 8 tension towers.

Failure to report promptly was a recurring issue. Only 10 of the 28 incidents were reported within 48 hours. Out of those, only 14 licensees submitted detailed failure investigation reports within one month. Delayed reporting affects root cause analysis and slows preventive action across the sector.

The causes of tower failures vary, but natural hazards were a dominant factor. In hilly areas, landslides and ground subsidence weakened tower foundations. The 400 kV Kishenpur–New Wanpoh line operated by POWERGRID is one example where unstable terrain contributed to structural damage. In other locations, towers collapsed under wind and storm loads higher than their design limits. Thunderstorms affected the 400 kV Gaya–Koderma line, while floodwaters released by a dam damaged towers along the 765 kV Gwalior–Agra line.

There were also failures due to human interference. In one instance, a 400 kV line between Silchar and Imphal was damaged due to theft and suspected sabotage involving explosives. Such incidents highlight the need for security measures, especially in remote or high-risk zones.

Substation equipment failures: Patterns and statistics

Substations form the nodes of the power grid where voltage is stepped up or down, and system protection is managed. Between July 2023 and December 2024, 162 failures of substation equipment rated at 220 kV and above were reported across 26 transmission and state utilities. The failures involved transformers, reactors, circuit breakers, instrument transformers, surge arresters, cables, isolators, and protection systems.

Breakdowns occurred across all equipment age brackets. Of the 162 cases, 22 pieces of equipment had failed within five years of commissioning. Another 38 were between five and ten years old, while 66 were between ten and twenty years old. Thirty-one had been in service for more than twenty years. In five cases, the equipment age was not disclosed. These figures indicate that both new and ageing equipment are susceptible to failure, albeit for different reasons.

Some failures were linked to ageing and poor condition monitoring. For example, a 315 MVA transformer installed in 1992 at Pappankalan-I failed after decades of operation. In other cases, design flaws and quality issues affected new equipment. A transformer at Kabulpur failed after just seven years in service, suggesting manufacturing or installation problems.

Environmental factors such as pollution, humidity, and lightning also contributed to failures. For instance, surge arresters at Mehrauli and Okhla failed due to pollution, while circuit breakers at Gorakhpur and Unnao failed due to ineffective protection systems or operational errors.

Consequences of failures

Tower collapses and equipment failures can cause widespread disruption. When a tower falls, adjacent towers are often affected due to cascading effects. On the 765 kV Bilaspur–Rajnandgaon line, a windstorm caused one tower to fall, which led to three more collapsing. Such incidents disconnect large parts of the transmission network and increase restoration costs.

Substation failures impact grid stability and system reliability. For example, the failure of a 500 MVA transformer at Muzaffarnagar affected power flow across several regions. Malfunctioning breakers and surge arresters can disable protection systems, increasing the risk of blackouts or equipment damage. At Sangrur, the failure of surge arresters left the infrastructure exposed to lightning strikes.

These failures also increase operational costs and reduce confidence in system reliability. Scheduled generation and load balancing become harder to manage, especially with increasing variable renewable energy (VRE) integration. In regions with high demand growth, the risk of load shedding or voltage instability rises.

Recommendations from the CEA

The CEA reports outline multiple corrective actions for both tower and substation failures.

For towers, the key recommendation is increased frequency of inspection and monitoring, especially in vulnerable areas. POWERGRID has shifted from biannual to monthly inspections in select locations. The Damodar Valley Corporation (DVC) has deployed drone-based inspection with thermal imaging to monitor critical tower sections. Accessing meteorological data from the India Meteorological Department (IMD) also helps in understanding wind loads, as seen in the case of the Bhadla–Jodhpur–Merta line.

In areas exposed to flooding or soil erosion, the reports recommend stronger foundations using pile structures. Revised design standards under IS 802:2015 with updated wind loading norms are encouraged for all new construction.

The reports also emphasise the need to deter theft and vandalism. In Haryana, HVPNL has involved local community volunteers to monitor transmission assets and prevent tampering.

For substation equipment, the reports advocate condition-based monitoring. This involves using real-time diagnostic tools and online monitoring systems to track equipment health. Examples include dissolved gas analysis (DGA) for transformers and partial discharge monitoring for cables and switchgear.

Utilities are advised to base their testing schedules on the condition and operating environment of equipment rather than fixed intervals. For instance, oil testing for transformers should be carried out annually or more frequently if early signs of degradation are observed.

Cleaning and maintenance in high-pollution zones is critical. The Okhla substation case illustrates the value of regular washing of surge arresters to prevent tracking and flashover. Replacing ageing equipment, such as the 1996-installed transformer at Udayathur, is another preventive measure.

The CEA also recommends developing a centralised platform to collect and analyse equipment data across utilities. This would enable trend analysis, risk-based maintenance planning, and early warning alerts.

Implementation challenges

To implement the recommended actions, several systemic issues need to be addressed. The current regulatory framework does not always require mandatory reporting within fixed timelines. Only 10 of the 28 tower failure cases were reported within 48 hours, limiting the ability to conduct a timely investigation.

Introducing standardised protocols for post-failure analysis and making them binding under grid codes or regulatory orders can improve compliance. Further, incentives for good performance—such as reduced transmission losses or fewer forced outages—can motivate utilities to improve asset maintenance.

Resource constraints are another concern. Many state utilities lack the funds or staff to adopt advanced monitoring systems. Budgetary support from central schemes or co-financing models involving the private sector could enable wider adoption.

Training and capacity building are also essential. Personnel need skills in predictive diagnostics, drone operations, and data interpretation. This requires ongoing investment in workforce development and collaboration with technical institutes.

Local engagement remains important. In states like Rajasthan, community members have been involved in monitoring to reduce theft and damage. Expanding such models could enhance asset security, particularly in remote or vulnerable regions.

Sector-wide coordination

To ensure coordinated action, the CEA proposes institutional mechanisms for knowledge sharing. Regular workshops and review meetings can help share good practices.

Collaborations with academic institutions and public sector R&D bodies could help design components better suited to Indian conditions. Tower designs, for example, can be made more resilient to extreme weather with input from civil engineering departments.

A key initiative under consideration is the creation of an integrated asset health monitoring system that spans all transmission licensees. This platform would collect equipment data, performance indicators, and fault history in a structured format. It would enable benchmarking, improve visibility, and guide long-term planning.

The Ministry of Power and Central Transmission Utility of India (CTUIL) could jointly steer this effort, with the CEA as the technical advisory body.

The road ahead

The findings in the CEA reports underscore the need for proactive grid maintenance. Both transmission towers and substation equipment are experiencing failures due to a combination of environmental, technical, and operational factors. As the grid expands and integrates more renewable energy, its vulnerability to such disruptions increases.

Moving forward, a stronger focus on predictive maintenance, weather-resilient design, and fast fault response will be essential. Digital tools such as drones, sensors, and analytics platforms offer new ways to monitor and respond to grid conditions.

Policy interventions will also play a role. Updating design codes, enforcing reporting timelines, and creating funding channels for modernisation can improve system reliability. In parallel, efforts to involve communities, train the workforce, and build institutional capacity will support long-term resilience.

A reliable grid is essential for industrial growth, agricultural productivity, and household welfare. As India transitions to cleaner and more decentralised energy systems, the reliability of its transmission backbone becomes even more important.

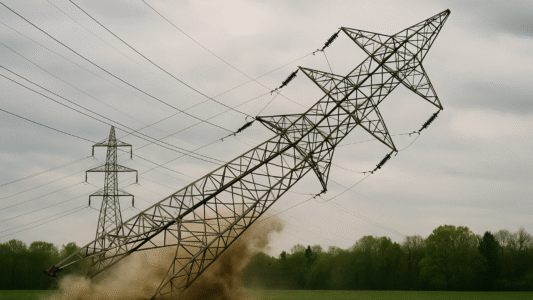

Featured photograph is for representation only